Detailed introduction

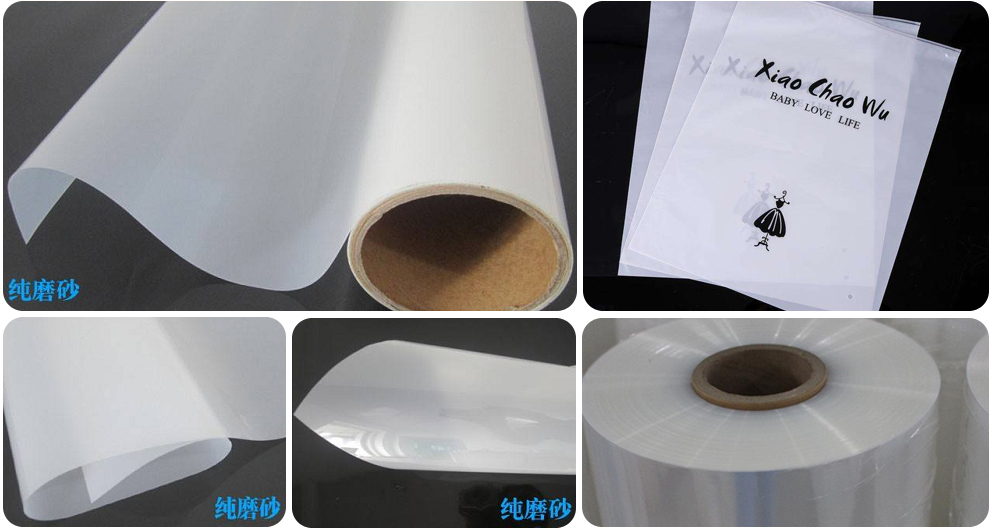

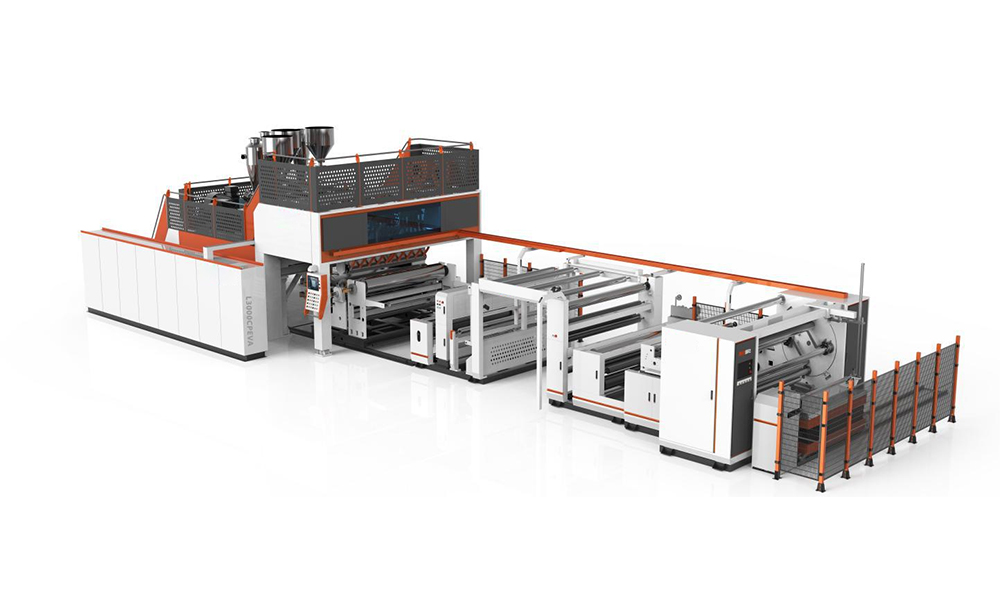

This unit is based on our company's many years of casting equipment manufacturing and customer's actual operation, continuously accumulating experience, and combining with foreign advanced technology to continuously update and transform, with high plasticization, easy operation, long machine life, power saving, etc. and foreign countries The cast film production unit with technical standards, with LDPE, LLDPE, HDPE and EVA as the main raw materials, can produce cast frosted film, embossed film, matte film and other products. The unit adopts advanced intelligent industrial control system, cooperates with automatic central coiling, and is equipped with imported tension controller, which can automatically change coils and cut off, ensuring safe and convenient operation, making the coiling stronger and smoother, and ensuring product quality. Greatly improve production efficiency, reduce production costs, and create greater value for customers.

Features

1. The screw is designed with high plasticizing capacity, good plasticizing, good mixing effect and high output:

2. Online automatic detection of film thickness and automatic adjustment of die head can be selected:

3. The cooling roller adopts special flow channel design, and the film cooling and shaping effect is good at high speed:

4. The film edge material is directly recycled online, which greatly reduces the production cost.

| Model | PB-LΦ75/110/75*2600 |

| Screw Diameter | 75/110/75mm |

| Screw L/D | 30:1 |

| Design Speed | 120m/min |

| Width | 2000mm |

| Total Power | 210KW |

| Thickness | 0.03~0.3mm x2200mm |

| Caoacity | 400kg/h |

| Layer Structure | A/B/C |

| Total Weight | 16T |

地址

地址

no.550 Kaifa Fifth Road Development Area In Ruian Eco Dev Zone Ruian Cith Zhejiang Province China

熱線電話

熱線電話

0086-13566176226

聯(lián)系郵箱

聯(lián)系郵箱

jacyplastic@hotmail.com

關(guān)于我們

產(chǎn)品中心

新聞動(dòng)態(tài)

24小時(shí)服務(wù)熱線

24小時(shí)服務(wù)熱線